Aluminum Extraction

The first step in the production process is the extraction of aluminum from bauxite ore. This is usually done through the Bayer process, which involves crushing the bauxite and mixing it with sodium hydroxide to extract alumina.

Welcome to AMERICAN ALUMINUM LLC. We are a leading manufacturer and provider of high-quality aluminum products for various industries. With years of experience, we have established ourselves as a trusted name in the aluminum manufacturing industry.

At AMERICAN ALUMINUM LLC, our mission is to deliver innovative and reliable aluminum solutions that meet the diverse needs of our clients. We specialize in the design, fabrication, and distribution of a wide range of aluminum products, including extrusions, sheets, plates, profiles, and more.

Quality is at the core of everything we do. We pride ourselves on employing state-of-the-art manufacturing techniques and utilizing the highest grade of raw materials to ensure the durability, precision, and integrity of our aluminum products. Our team of skilled engineers and technicians work meticulously to meet and exceed industry standards while adhering to stringent quality control measures.

AMERICAN ALUMINUM LLC provides surface finishing and coating services for aluminum products. This can include processes such as anodizing, powder coating, painting, polishing, or brushing to enhance the appearance, durability, and corrosion resistance of the aluminum surfaces. The company may offer assembly and integration services, where they assemble different aluminum components into complete products or subassemblies. This can involve joining techniques like welding, fastening, or bonding.

The first step in the production process is the extraction of aluminum from bauxite ore. This is usually done through the Bayer process, which involves crushing the bauxite and mixing it with sodium hydroxide to extract alumina.

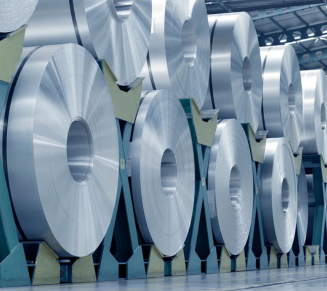

The extracted alumina is then sent to smelters, where it undergoes the Hall-Héroult electrolytic process. In this process, the alumina is dissolved in molten cryolite and subjected to an electric current, which separates the pure aluminum from other impurities.

After extrusion, the aluminum profiles may undergo further machining or fabrication processes such as cutting, drilling, milling, bending, or welding. These processes help transform the extruded profiles into finished products or components.

QC/QA Inspection

Top-notch Quality

Expert Employees

Satisfied Customers

Throughout the production process, quality control measures are implemented to ensure that the aluminum products meet the required standards. This includes inspection of raw materials, dimensional checks, testing for mechanical properties, and overall product quality assurance.

If necessary, the aluminum components may be assembled into larger products or subassemblies. This can involve additional processes like welding, fastening, or bonding.

The company may provide custom design and engineering services for aluminum products based on the specific requirements and specifications of clients. This can include product development, prototyping, and CAD/CAM design.

The company may specialize in the extrusion process, producing custom aluminum extrusions with various shapes, sizes, and profiles. This can include standard shapes like T-slots, angles, channels, or customized profiles as per client specifications.

The company may offer sheet metal fabrication services using aluminum sheets. This can include cutting, bending, welding, punching, and CNC machining to create precise components or assemblies.

Surface treatment processes are often applied to improve the appearance, durability, and corrosion resistance of the aluminum products. Common surface treatments include anodizing, powder coating, painting, polishing, or brushing.